Development of an automatic black garlic fermenter: A Vietnamese innovation

27/10/2025TN&MTAs Vietnam’s agriculture rapidly transforms toward high technology, a group of young researchers from the University of Agriculture and Forestry, Ho Chi Minh City, has developed an automatic black garlic fermenter with a capacity of 10 kilograms per batch. Entirely designed and fabricated domestically, the device allows remote monitoring and control via smartphone, marking a new step forward in smart agri-processing and showcasing the creativity and technological independence of Vietnamese engineers: Ho Van Dung, Khuong Anh Son, Pham Viet Hung, Vo Cong Anh, Le Thi Kim Anh, Nguyen Thanh Cuong, and Tran Khang.

Vietnamese researchers developed an automatic black garlic fermenter to replace costly imported models and ensure consistent quality under precise temperature and humidity control

Turning ordinary garlic into a high-value product

Black garlic, a naturally fermented product from fresh garlic, is increasingly popular for its high nutritional value and antioxidant properties. However, production requires strict control of temperature, humidity, and time, while most fermenters on the Vietnamese market remain imported and expensive. Manual models, meanwhile, often yield inconsistent quality and consume excessive energy and time.

Recognizing this gap, the research team embarked on the project titled “Research, design, and fabrication of an automatic black garlic fermenter with a capacity of 10 kg per batch.”

Their objective was clear: to create an automatic fermentation system capable of maintaining stable temperature and humidity, precisely controlling each fermentation stage, and enabling remote supervision through modern technology.

The team aimed to deliver a system that is energy-efficient, cost-effective, and capable of producing consistent, high-quality black garlic suitable for small-scale producers.

Industry 4.0 steps into Vietnam’s agri-kitchen

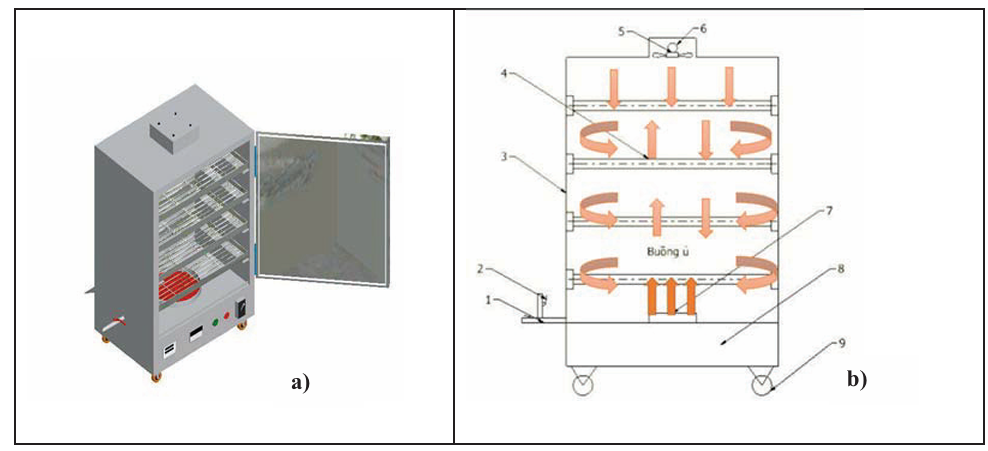

Using Inventor 2018 software, the team designed a multi-tray stainless-steel (304) fermentation chamber with optimized airflow. Heat is generated through an electric resistance element and distributed by forced convection fans, while a water tray ensures constant humidity. The sealed chamber is fitted with casters for easy mobility and insulation to minimize heat loss.

The control system was programmed using Arduino IDE, integrating DHT22 temperature–humidity sensors, an LCD display, and the Blynk 2.0 mobile application for real-time monitoring via smartphone. The system operates fully automatically through three programmed stages: heating, fermentation, and cooling.

3D model of the automatic black garlic fermenter

The team’s most notable success lies in automation, operators no longer need to manually monitor the process for 30 days. Every stage is preprogrammed, with progress viewable remotely, symbolizing how smart agriculture is moving closer to Industry 4.0.

According to the 3D model, the fermenter consists of key components: control panel, fermentation chamber, garlic trays, fan, exhaust duct, water tray, heating resistor, and caster wheels — all logically arranged to optimize heat circulation.

Black garlic: a new symbol of Vietnamese innovation

The system was tested over a 30-day fermentation cycle with a 10 kg batch capacity. Results showed the machine operated stably at approximately 80% efficiency, producing black garlic with uniform color, elasticity, mild aroma, and pleasant sweetness, consistent with consumer sensory standards.

Sensory evaluation based on five-point Likert scales rated all criteria, such as: color, aroma, taste, texture, appearance, and convenience, from “good” to “very good.” Color transformation followed a clear progression: Day 4: light brownish-yellow; Day 10: darker tone; Day 20: dark brown; Day 30: glossy black with a signature caramel aroma.

When compared with commercial models such as OSATA, LUVA, SUNCA, and VN100, the team’s fermenter achieved comparable performance within the standard 30-day fermentation cycle, reduced power consumption by 15–20%, and uniquely featured Internet-based monitoring, a capability absent in similar-capacity models. Production costs were 40% lower than imported units, with 100% localized materials and components.

Beyond being a machine, this is also a practical training model that allows students to learn about mechanical design, electronics, programming, and agricultural automation in an integrated system.

Toward sustainable, smart agri-processing

The team concluded that their black garlic fermenter operates stably, with a 30-day automatic fermentation cycle, sensor-based control of temperature and humidity, and 80% operational efficiency, producing safe, high-quality black garlic.

This research opens new possibilities for intelligent agri-processing technologies, applicable not only to black garlic but also to onion, ginger, turmeric, and medicinal herbs requiring controlled fermentation environments.

Future directions include standardizing operating procedures, scaling up capacity to 20–30 kg per batch, and integrating multi-chamber IoT control systems for synchronized operation.

In the long term, the team hopes to transfer the technology to cooperatives and small producers. If every craft village could access a locally made smart fermenter, the value of Vietnamese agricultural products would increase manifold.

The story of this 10 kg automatic black garlic fermenter is more than a scientific success. It is a symbol of the harmony between knowledge, creativity, and technological self-reliance.

From Inventor 2018 blueprints to the glowing fermentation chambers in their lab, these young engineers have proven that Vietnamese innovators can master smart agricultural technology, starting from something as simple as a clove of garlic.

Viet Anh

Source: Based on the research project “Research, design, and fabrication of an automatic black garlic fermenter with a capacity of 10 kg per batch” conducted by Ho Van Dung, Khuong Anh Son, Pham Viet Hung, Vo Cong Anh, Le Thi Kim Anh, Nguyen Thanh Cuong, and Tran Khang at the University of Agriculture and Forestry – Hue University, in collaboration with Idea Technology Corporation JSC