Binh Minh Plastics takes green initiatives in alignment with ESG standards

02/05/2024TN&MTThe global trend towards green transformation is gaining momentum, particularly within the manufacturing sector. Plastic manufacturing companies, such as Binh Minh Plastic Joint Stock Company, recognize the growing importance of embracing green and sustainable practices.

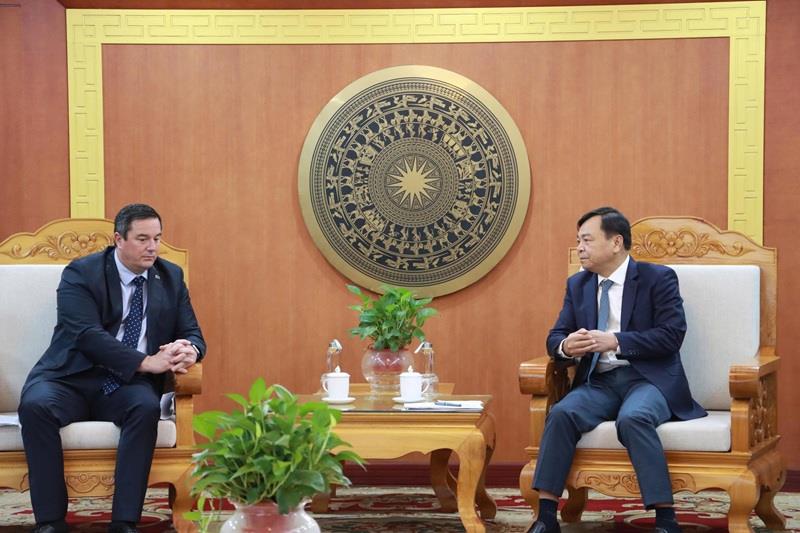

To gain a better understanding of the company's preparation in this process, a discussion session was conducted by Mr. Chowmahitorn Petpaisit, Director of Northern Binh Minh Plastics Company Limited, with the journalist from the Natural Resources and Environment Magazine.

Mr. Chowmahitorn Petpaisit, Director of Northern Binh Minh Plastics Company Limited

At the 26th United Nations Climate Change Conference (COP26), Vietnam committed to achieving Net-Xero emissions by 2050. As a manufacturing enterprise with potential environmental impacts, what action plans does the company have in place to contribute to the government's overall goal?

During its entire production and business process, and especially since 2007, Binh Minh Plastic Joint Stock Company has been concerned about the impacts its activities may have on the environment. Currently, all of Binh Minh Plastic's products are made from non-toxic raw materials, do not affect users' health, and are environmentally friendly. In addition, we encourage users to install and use products for a long time in commercial activities to reduce environmental waste. Besides, in terms of production technology, we have continuously improved and used advanced and modern technologies to reduce waste and emissions from production and business activities into the environment.

In the trend of sustainable development and the world's green transition demand, as a company holding approximately 28% market share in Vietnam, what specific action plans does the enterprise have in place?

We continuously implement green, environmentally responsible transformation activities into production and business activities. Specifically, the primary raw materials for production, including PVC, HDPE, and PP... are selected and purchased from reputable manufacturers, complying with quality management activities according to ISO 9001 and environmental management. According to ISO 14001, such as TPC Vina, AGC VN, Borouge, Sabic, Basell...

In addition, Binh Minh Plastics has succeeded in establishing a closed automation system from input materials to final products and continues to invest in modern, energy-saving machinery and equipment from European countries. Europe. Thanks to that, in addition to the ability to meet national and international quality standards, Binh Minh Plastic's products have successfully applied an environmentally friendly additive system (no heavy metals). The product's achievement is receiving the UK's Water Safety Product Certificate to ensure customers have clean water sources that are also good for the environment.

Not stopping there, we also started using renewable energy, such as solar energy, for the entire operating process, production, and business.

Northern Binh Minh Plastics Company Limited located in Pho Noi A Industrial Park, Van Lam District, Hung Yen Province

When it comes to sustainable development nowadays, one cannot overlook ESG standards (Environmental, social, and governance). How does the company perceive this set of standards?

ESG is a method of evaluating and operating a business beyond just focusing on profits. As global sustainability and environmental impact challenges increase, we cannot stand idly by and ignore this. ESG can help us understand the internal and external ecosystems in which our business operates.

In addition, ESG can support Binh Minh Plastics in growth opportunities, reduce costs, and strengthen our brand in Vietnam. Therefore, we are committed to applying ESG standards in our production and business activities.

How does the company plan to implement ESG?

In its mid-term business development strategy, Binh Minh Plastics applies ESG to determine energy consumption, water consumption, and the amount of waste generated. In addition, we also plan to train each department and employee on ESG standards. Thanks to applying ESG standards, our social, environmental, and governance responsibilities are also enhanced, synchronized, and monitored by international standards.

As a business operating in the manufacturing industry, we face energy efficiency and waste management as two challenges when applying ESG. At the early stages of ESG adoption, we may have to spend significant resources and time to comply with the standards within the ESG framework. However, in the long run, meeting ESG standards on social and governance factors, especially the environment, helps Binh Minh Plastics achieve business goals and innovation in production activities. , helping the company develop sustainably.

This is consistent with the world's transformation trend when investors and consumers are increasingly interested in products responsible for society, especially the environment. A successful company not only brings profits but also must be accountable to society and the environment where the factory is located.

Some typical products of Binh Minh Plastic

Vietnam is nearing the completion of the draft 'Global Agreement on Plastic Pollution,' with the Ministry of Natural Resources and Environment spearheading the consultation process. From a business standpoint, what insights or contributions can you offer regarding this initiative?

I fully support this draft proposed by the Ministry of Natural Resources and Environment. From a business perspective, this agreement will enhance awareness among both consumers and plastic manufacturers to reduce the use and production of single-use plastic products, promote circular production models, and encourage cleaner production. Furthermore, encouraging people to segregate plastic waste will also benefit future plastic recycling business operations.

Dinh Thanh