Application of nanobubble technology in seafood preservation: Potentials and challenges

13/10/2025TN&MTAs the demand for food safety and reduction of post-harvest losses continues to increase, technological innovations for seafood preservation and treatment are gaining growing attention from researchers. One emerging “green” solution is nanobubble (NB) technology, which has been extensively studied in medicine, water treatment, and aquaculture, and is now being explored for seafood preservation. According to researchers Vu Dinh Tien and Vu Duy Hung from Hanoi University of Science and Technology, this technology promises breakthrough improvements, yet challenges remain regarding cost, standardized protocols, and the need for further research to optimize its application in the aquaculture and seafood industry.

The need for new technologies in seafood preservation

Post-harvest preservation is a critical stage in the seafood value chain, directly determining product quality, safety, and economic value. However, under high ambient temperatures and limited cold-chain infrastructure, fresh seafood is highly prone to spoilage caused by microorganisms, endogenous enzymes, and natural oxidation reactions. These changes occur rapidly, shortening shelf life, causing economic losses, and reducing marketability.

Traditional preservation methods such as icing, freezing, chemical treatment, or irradiation have been applied, but they still face limitations in long-term efficiency, operational cost, and risks of chemical residues. Therefore, developing environmentally friendly and energy-efficient technologies that can maintain seafood quality and extend shelf life has become a key research direction.

In this context, nanobubble technology is considered a promising approach. In the food and aquaculture industries, nanobubbles using gases such as oxygen, ozone, or nitrogen are expected to enhance dissolved oxygen, control pathogenic microorganisms, support washing and disinfection, and thus improve product quality and prolong storage time.

Mechanisms and generation methods of nanobubbles

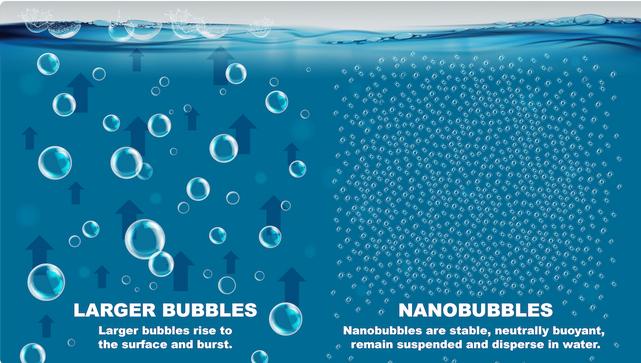

Nanobubbles, also referred to as ultra-fine bubbles, are microscopic gas cavities suspended in liquid with diameters smaller than 1 µm. They can exist as surface nanobubbles (attached to solid–liquid interfaces) or bulk nanobubbles (dispersed within the liquid). NB exhibit unique physicochemical properties such as high gas solubility, high zeta potential, the ability to generate free radicals, large specific surface area, and energy release upon collapse. Due to their extremely small size and low buoyancy, they can remain suspended for long periods (from hours to days), enhancing mass transfer efficiency.

These characteristics have led to growing interest in nanobubble applications across various sectors, particularly aquaculture and seafood preservation.

Currently, there are five main methods used to generate nanobubbles:

Pressurized dissolution method – gas is dissolved in water under high pressure, then rapidly depressurized, forming nanobubbles as gas is released.

Venturi method – based on pressure differentials as water flows through a constricted pipe, drawing in air and generating fine bubbles upon exiting the expansion zone.

Swirling flow method – utilizes vortex and shear forces within flowing water to separate dissolved gases and produce nanobubbles.

Porous membrane method – gas is forced through a membrane with micro- to nanoscale pores, creating ultra-fine gas bubbles dispersed in water.

Electrolysis method – relies on water electrolysis, where hydrogen and oxygen gases are produced at the electrodes, simultaneously forming nanobubbles.

Each generation method offers distinct advantages in terms of bubble size, density, gas solubility, and energy consumption. Among them, the pressurized dissolution and Venturi-based systems are currently the most practical for industrial applications.

When dispersed in water, nanobubbles rise extremely slowly, maintain a large specific surface area, and carry a negative surface charge, which stabilizes them and prevents coalescence or collapse. This stability helps maintain high levels of dissolved oxygen (DO), improve gas exchange, and ensure water quality during seafood storage. A nanobubble-enriched water environment mitigates oxygen depletion, inhibits microbial decomposition, and thus prolongs the freshness of seafood products.

Research results indicate that seafood stored in nanobubble water retains higher freshness and sensory quality than that preserved by conventional methods. The effectiveness of nanobubble technology in seafood preservation primarily arises from its ability to increase DO, maintain aerobic conditions, and inhibit microbial and biochemical degradation, ultimately enhancing product quality and shelf life.

Applications in aquaculture and post-harvest preservation

Studies have demonstrated that nanobubble technology can be effectively applied in both stages of the seafood production chain: aquaculture and post-harvest preservation.

Applying nanobubble technology in aquaculture helps maintain higher and more stable DO concentrations, significantly improving water quality. The uniformly dispersed nanobubbles enhance oxidation of organic matter and the conversion of toxic compounds, thereby reducing concentrations of NH₃, NO₂⁻, and NO₃⁻ in culture ponds.

Improved water quality leads to higher growth rates and survival of aquatic species compared with conventional aeration methods. This dual benefit—enhancing productivity while minimizing environmental pollution—makes nanobubble systems an attractive solution for sustainable aquaculture.

After harvest, seafood is vulnerable to spoilage due to oxygen depletion, biochemical reactions, and microbial activity. Using nanobubble-enriched water during live fish storage and transportation helps maintain high DO levels, stabilize tank conditions, and reduce fish stress and mortality during transport.

Furthermore, applying oxygen or ozone nanobubbles in fresh fish preservation has been shown to maintain freshness, color, and odor longer than in control samples. The high DO concentration suppresses anaerobic reactions and protein degradation, extending storage time without chemical preservatives.

Thus, nanobubble technology delivers measurable benefits across both aquaculture and preservation stages—enhancing yield, reducing disease risk, and maintaining product freshness—thereby contributing to clean production and sustainable development of the seafood industry.

Development potential and future challenges

Nanobubble technology offers significant potential to enhance seafood quality and sustainability. It can effectively extend the storage period of fresh products, reduce spoilage and food waste, and preserve sensory and nutritional attributes over longer periods. As a natural and physical preservation method, it reduces reliance on chemical preservatives and improves food safety through microbial control. By enabling longer-distance transport of high-quality fresh seafood, the technology expands market access and export opportunities, contributing to a more sustainable and competitive seafood sector.

Nevertheless, further research is required to refine the design and operation of nanobubble generators, optimizing parameters such as gas flow rate, pressure, impeller material, and reactor chamber dimensions to ensure operational stability and durability in large-scale applications. Comprehensive assessments of energy consumption and cost–benefit performance are also essential to demonstrate economic feasibility, given the relatively high initial investment.

In summary, nanobubble technology represents a promising, environmentally friendly innovation for Vietnam’s aquaculture and seafood industry, with strong potential to enhance product quality, reduce post-harvest losses, and promote sustainable production aligned with global green growth trends.

Minh Thao

Source: The 2025 National Conference on post-harvest preservation, processing of agricultural, forestry, and fishery products and agricultural Mechanization